A Costly Surprise: “How floor planning bugs ” Can Became a Construction Nightmare

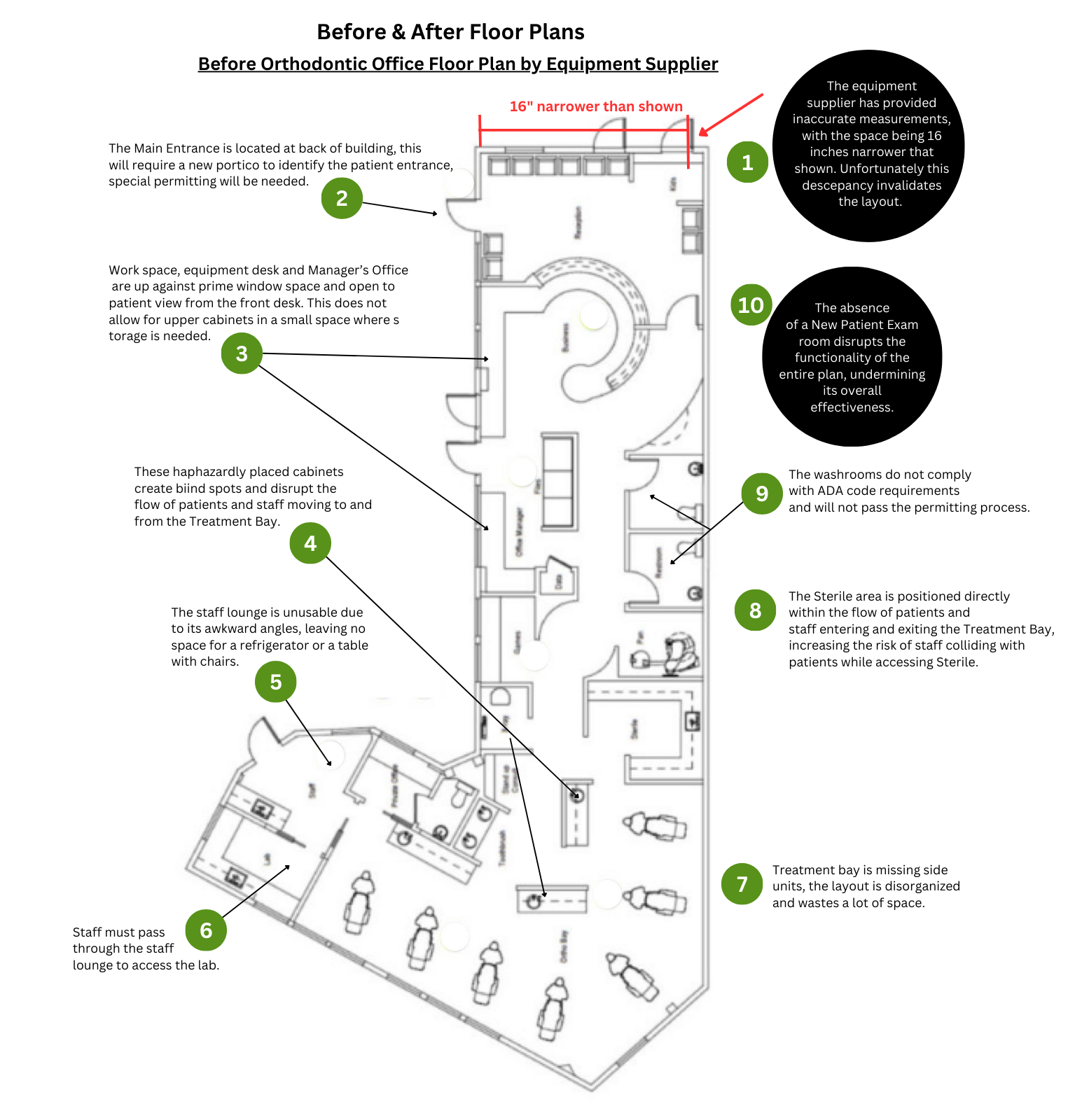

Building a new orthodontic practice should be exciting. Unfortunately, many projects face unexpected construction problems caused by errors in early floor plans. A single mistake — such as discovering the space is 16 inches narrowerthan shown on drawings — can trigger major delays, rising costs, and overwhelming stress.

These issues are far more common than most doctors realize. The good news is that they can be avoided with a proper design review before construction begins.

The Hidden Risks in Orthodontic Office floor Plans

Industry research and our own project history show that over 85% of field revisions come from incomplete or inaccurate plans. Several recurring issues contribute to these setbacks.

1. Inaccurate or Assumed Measurements

Even a one-inch measurement error can grow into a costly framing problem once walls go up.

2. Poor Space Utilization

Awkward cabinet placement, wasted window lines, and inefficient circulation make daily operations harder and reduce long-term productivity.

3. ADA Compliance Failures

Incorrect restroom dimensions or clearances can prevent your project from passing review. These mistakes often delay permit approvals by weeks or months.

4. Equipment Supplier Layout Pitfalls

Many doctors receive complimentary layouts from equipment suppliers. Although convenient, these drawings frequently:

Misplace the entrance

Waste valuable natural light

Ignore patient and staff flow

Overlook ADA requirements

Include disclaimers such as “Not for Construction”

Without expert review, these oversights can lead to expensive revisions during construction.

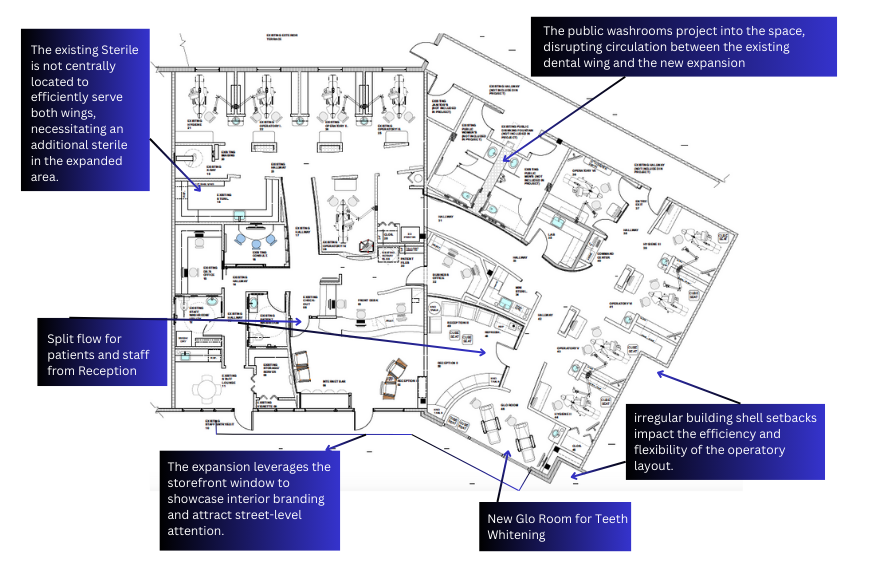

A real example involved a supplier plan that placed a back entrance in the wrong location, used the prime window line for administrative staff, and positioned Sterile where it disrupted the treatment bay. These issues required significant redesign to protect the project timeline and budget.

How Green Curve Studio Transforms Flawed Floor Plans

Our specialized orthodontic workflow system helps identify and correct hidden issues before construction begins. By focusing on accuracy, efficiency, and patient experience, we strengthen the entire design.

✔ Relocated Main Entrance

We repositioned the entrance to the front of the building to create a strong first impression with a prominent logo wall and dramatic ceiling detail.

✔ Improved Front Desk and Administration Areas

Ergonomic work zones, optimized storage, and better site lines help staff work smoothly, even during busy hours.

✔ Corrected ADA Non-Compliance

Restrooms were redesigned to meet ADA requirements, ensuring the space could pass permitting without delays.

✔ Streamlined Treatment Bay Flow

We organized the chair layout, cabinetry, and pathways to improve efficiency and create a calm, comfortable experience for patients.

✔ Centralized Sterile

By placing Sterile in a more accessible and discreet location, we improved workflow and kept clutter out of patient view.

✔ Created Dedicated Staff and Doctor Entrances

Clear circulation paths help separate front-of-house activity from clinical movement.

These changes prevented re-framing, reduced confusion during construction, and supported long-term operational success.

Why Critical Errors Are So Common in Orthodontic Plans

Many initial floor plans come from:

Equipment suppliers

General practice architects

Local draftsmen

Designers without orthodontic specialization

Although these layouts may look polished, they often miss crucial details such as workflow, ADA compliance, and clinical efficiency. Because they’re offered at little or no cost, the plans lack the depth and coordination needed for a successful build.

Bad design may not harm a patient, but it can harm your peace of mind, your budget, and your long-term production potential.

How We Caught a Major Dimensional Error — From Out of State

How We Caught a Major Dimensional Error—From Out of State

Clients often ask how we identify mistakes without being local. The answer is simple: process, not proximity.

Before we begin any layout, we:

Compare the provided drawings to original building plans

Verify critical dimensions

Review site photos, surveys, and structural documents

Identify inconsistencies between all sources

In one project, an equipment supplier provided incorrect dimensions. Several teams unknowingly reused the same file, compounding the error. By checking the measurements against the building’s original drawings, we caught the 16-inch discrepancy early and prevented a full re-framing.

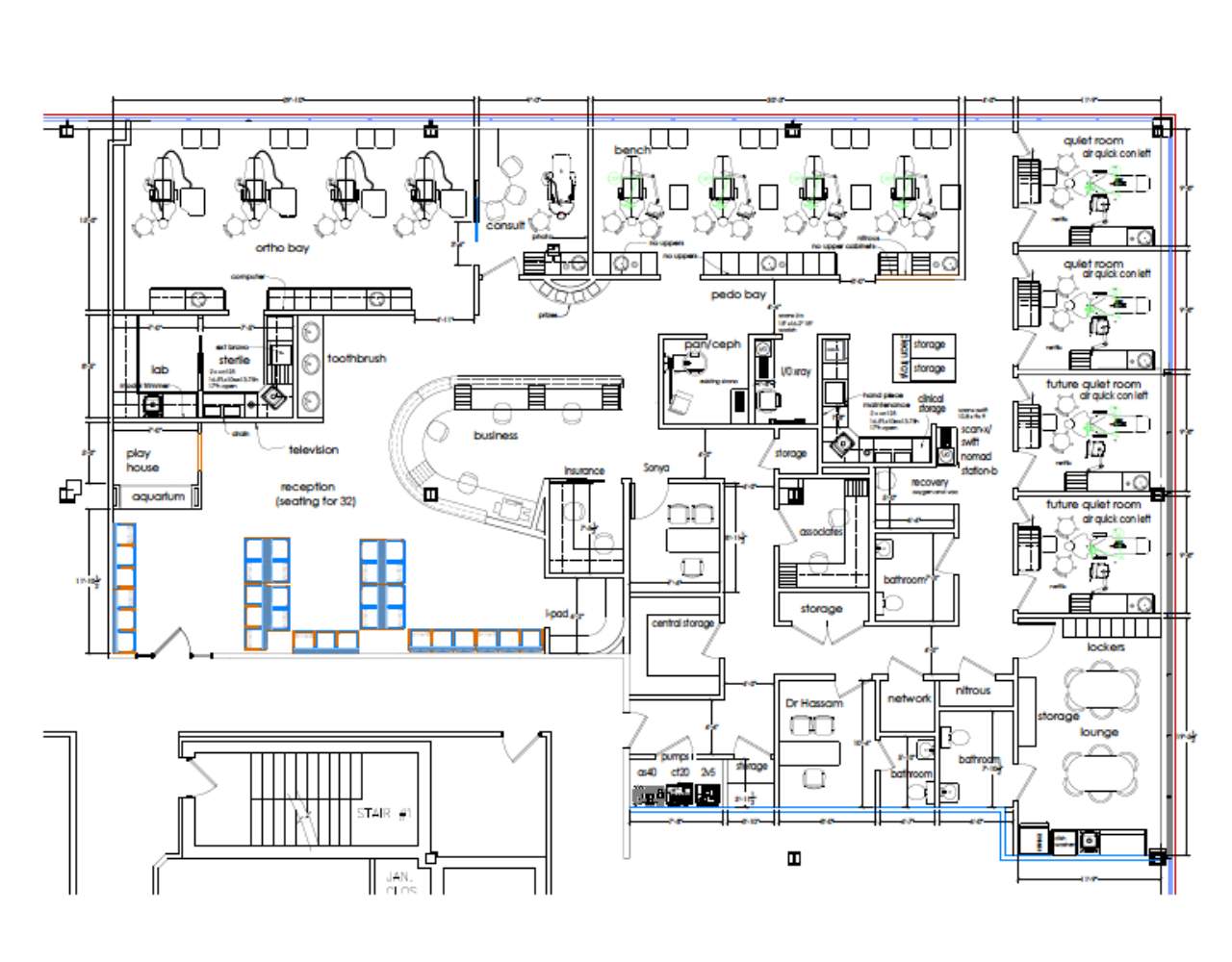

Orthodontic office floor plan, project located in Tampa, FL

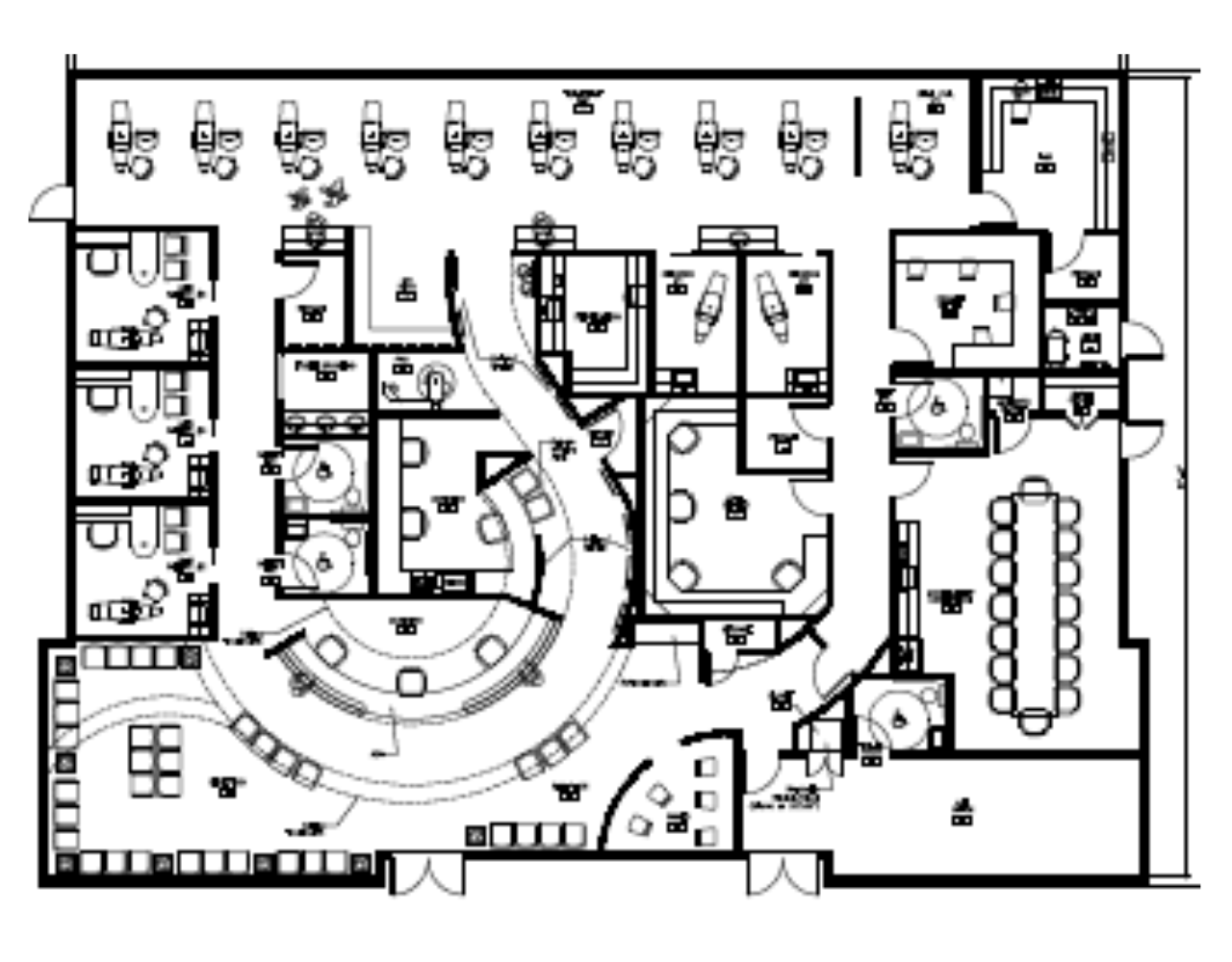

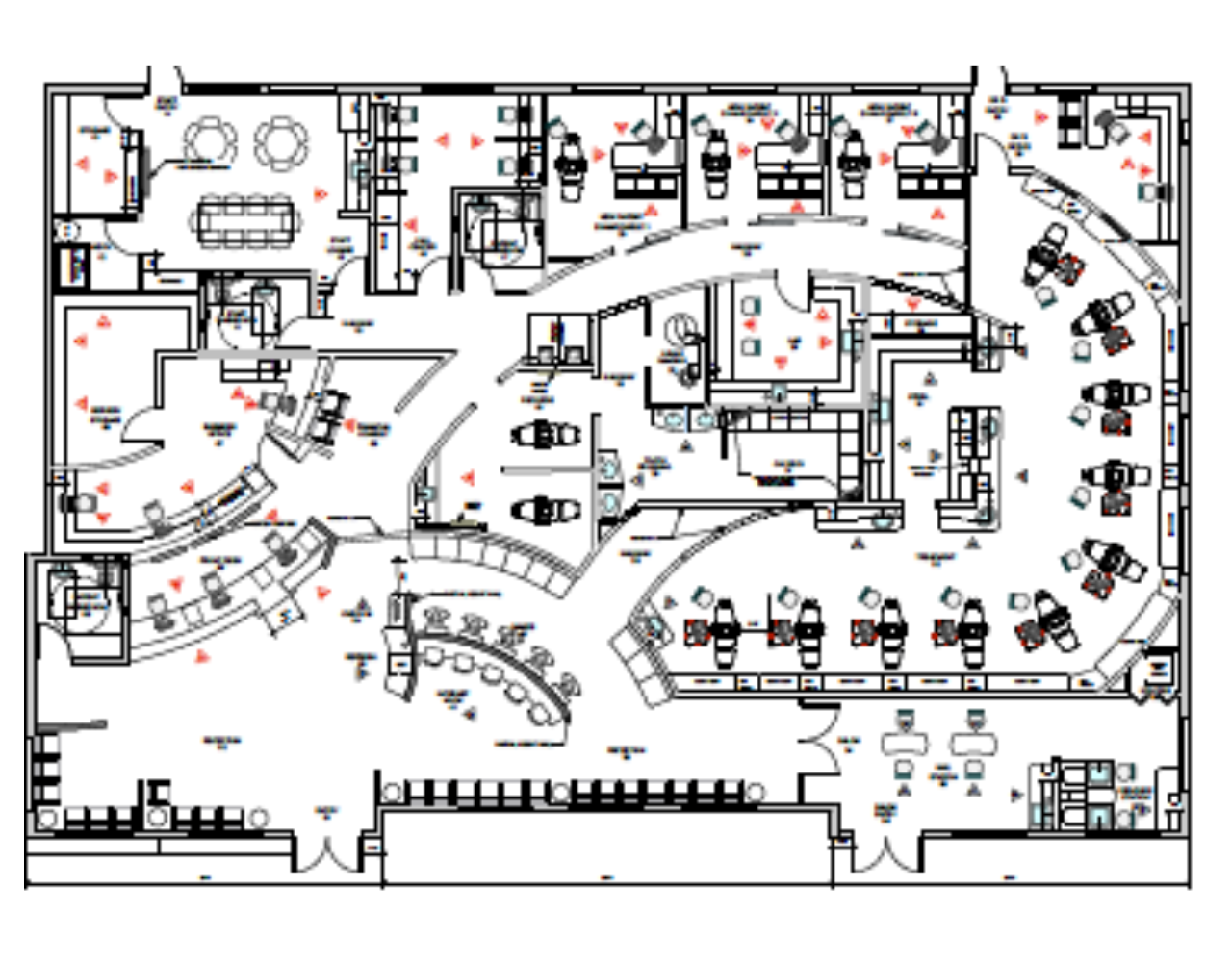

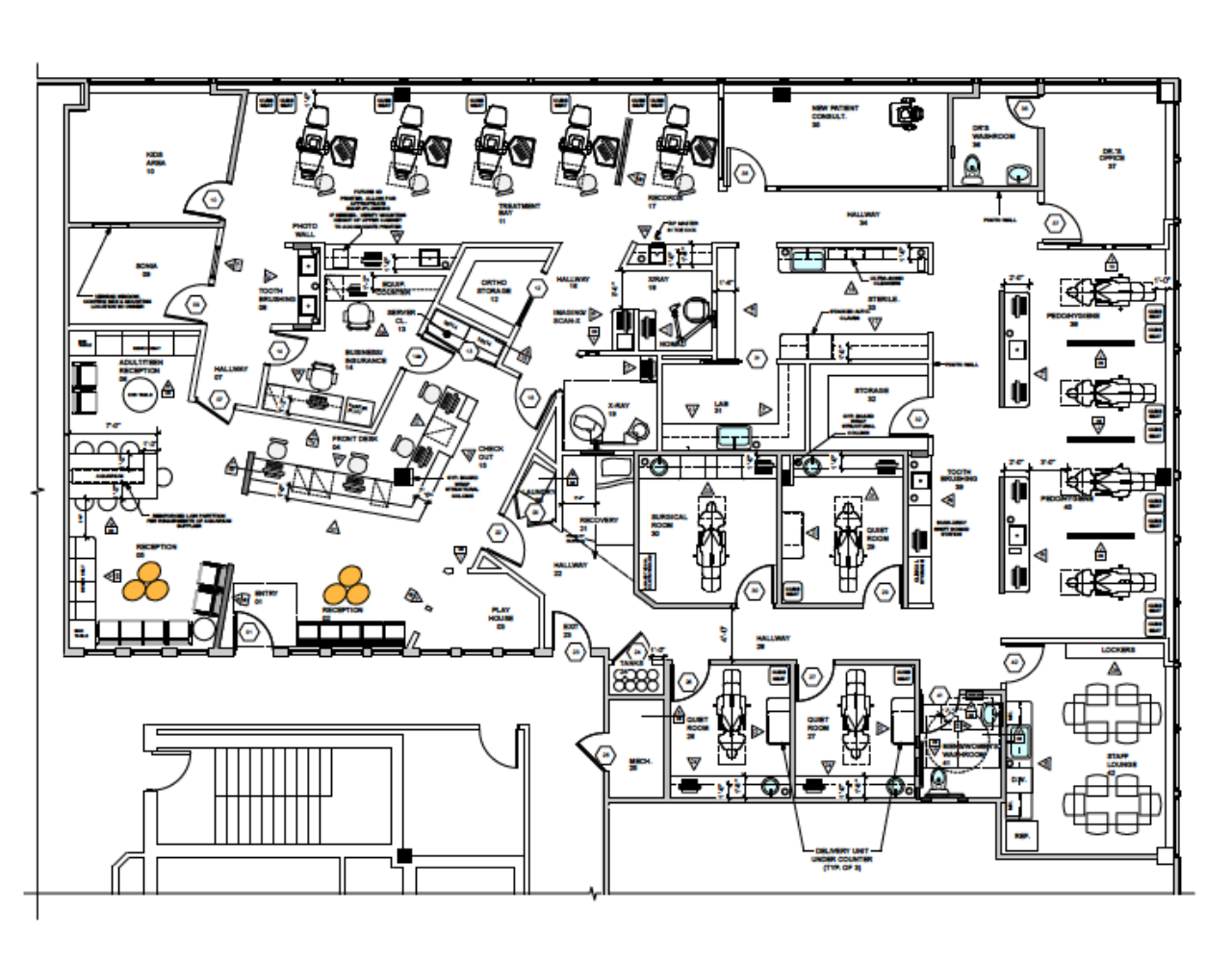

Pediatric Dental/Orthodontic office floor plan, project located in Clifton, NJ

Before & After: Real-World Floor Plan Corrections

Orthodontic Floor Plan – Before and After

Our redesigned Tampa orthodontic office plan improved workflow, addressed ADA issues, and resolved space constraints that the original layout overlooked.

Pediatric / Orthodontic Floor Plan – Before and After

In Clifton, NJ, we reworked a complex pediatric/orthodontic combination space. The new plan established a clean flow, improved zoning, and created a cohesive experience on a modest budget.

These examples show how strategic planning protects your project from costly mistakes.

How to Know Whether Your Designer or Architect Is Truly Qualified

Modern design software makes it easy to create beautiful renderings — even of spaces that have never been built. Because of this, it’s important to look beyond the images.

Red flags to watch for:

Only one or two dental or medical projects in their portfolio

No photographs of completed projects

Vague claims such as “We specialize in dental offices” without evidence

Drawings stamped “Not for Construction”

Lack of questions about workflow, ergonomics, or sterilization

A qualified orthodontic design team should understand how your daily operations work and should challenge plans that could slow production or create long-term frustration.

Q&A: Your Most Common Orthodontic Floor-Plan Questions

Who pays for re-framing when dimensions are wrong?

If you forwarded a “Not for Construction” layout to your contractor, you typically assume the liability. Most doctors don’t know this—and only discover it after demo is complete.

Are critical layout errors really that common?

Yes. Roughly 8 out of 10 orthodontic layouts we review contain at least one serious issue.

What’s the biggest cause of construction delays?

Underdeveloped floor plans lacking critical detail for mechanical, plumbing, electrical, and cabinetry coordination.

Can bad layout decisions affect my practice long-term?

Absolutely. Poor flow can permanently limit production, increase staff fatigue, and diminish patient experience.

Before you submit for permits or start construction, get a professional Layout Evaluation.

It can save tens of thousands of dollars and months of stress.

Often, equipment supplier drawings come stamped with “Not for Construction” disclaimers. Yet, if you accept these layouts and pass them on to your contractor or architect you’re effectively taking ownership of any errors within them.

Protect Your Investment Before You Build

Before submitting for permits or starting construction, get a professional Layout Evaluation. A detailed review can save you tens of thousands of dollars, prevent construction delays, and ensure the space supports your practice for years to come.